Aircraft Components

In this section you will learn how aircraft are designed and constructed, including materials used, and structural components.

All of information below are referenced from the Pilot’s Handbook of Aeronautical Knowledge

Aircraft Components

Major Components

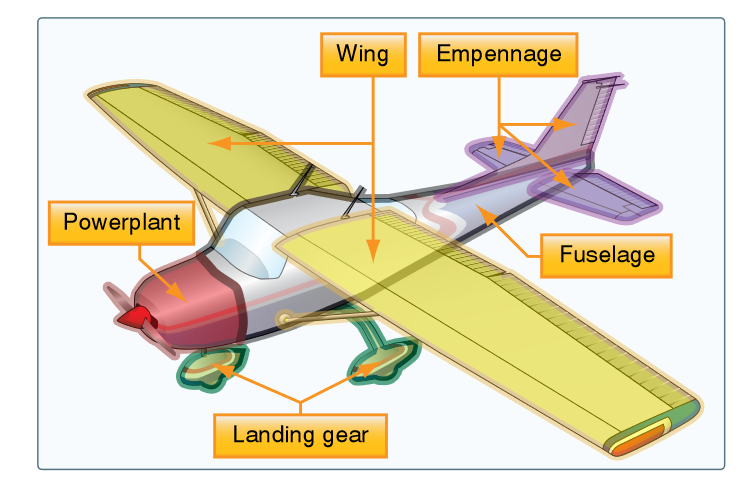

Most airplane structures include a fuselage, wings, an empennage, landing gear, and a powerplant.

Fuselage

The fuselage is the central body of an airplane and is designed to accommodate the crew, passengers, and cargo. It also provides the structural connection for the wings and tail assembly.

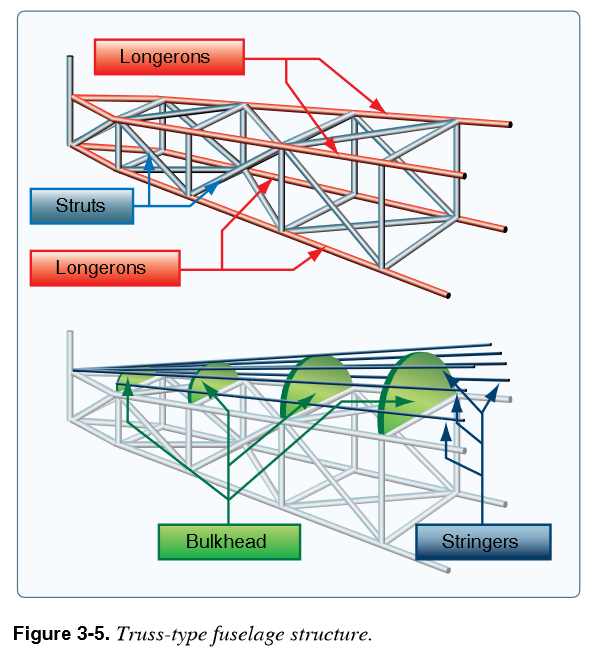

Truss Structure

The main drawback of truss structure is its lack of a streamlined shape. As technology progressed, aircraft designers began to enclose the truss members to streamline the airplane and improve performance. This was originally accomplished with cloth fabric, which eventually gave way to lightweight metals such as aluminum. In some cases, the outside skin can support all or a major portion of the flight loads. Most modern aircraft use a form of this stressed skin structure known as monocoque or semimonocoque construction.

The most popular types of fuselage structures used in today’s aircraft are the monocoqueand and semimonocoque

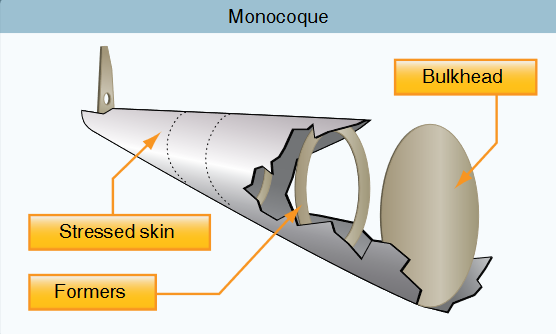

Monocoque

Monocoque construction uses stressed skin to support almost all loads much like an aluminum beverage can.

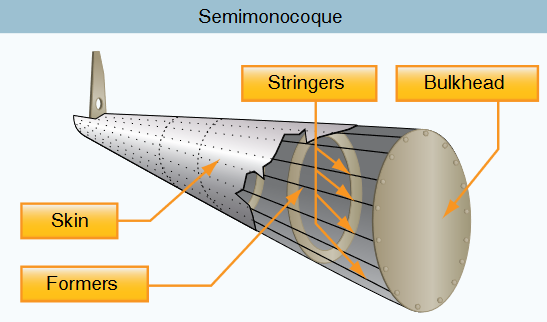

Semimonocoque

Semimonocoque construction, partial or one-half, uses a substructure to which the airplane’s skin is attached. The substructure, which consists of bulkheads and/or formers of various sizes and stringers, reinforces the stressed skin by taking some of the bending stress from the fuselage. The main section of the fuselage also includes wing attachment points and a firewall. On single-engine airplanes, the engine is usually attached to the front of the fuselage. There is a fireproof partition between the rear of the engine and the flight deck or cabin to protect the pilot and passengers from accidental engine fires. This partition is called a firewall and is usually made of heat-resistant material such as stainless steel. However, a new emerging process of construction is the integration of composites or aircraft made entirely of composites.

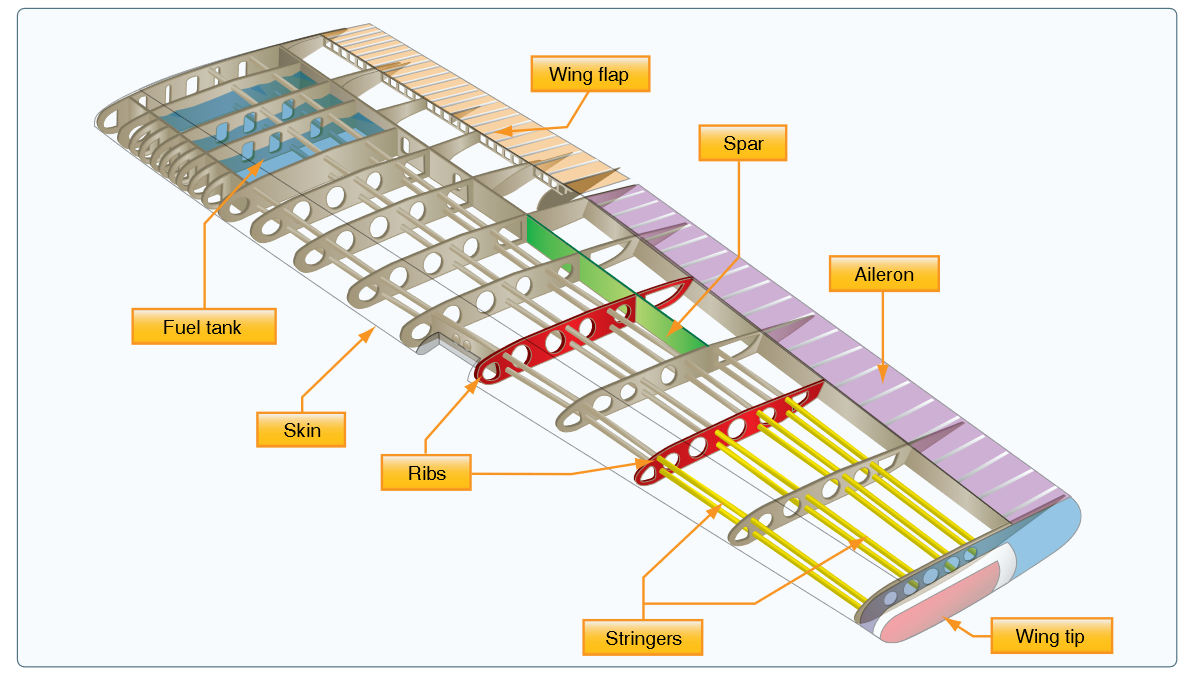

Wings

The wings are airfoils attached to each side of the fuselage and are the main lifting surfaces that support the airplane in flight. In most modern airplanes, the fuel tanks are either an integral part of the wing’s structure or consist of flexible containers mounted inside of the wing.

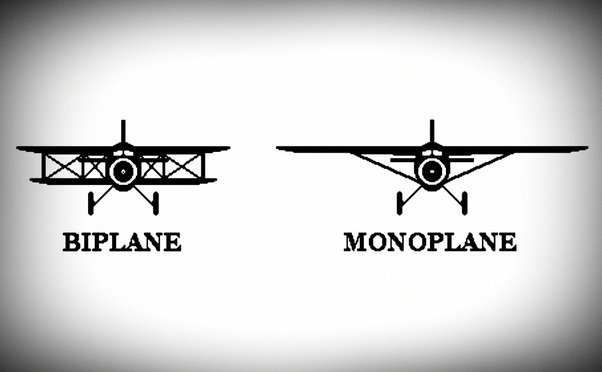

Wings may be attached at the top, middle, or lower portion of the fuselage. These designs are referred to as high-, mid-, and low-wing, respectively. The number of wings can also vary. Airplanes with a single set of wings are referred to as monoplanes, while those with two sets are called biplanes.

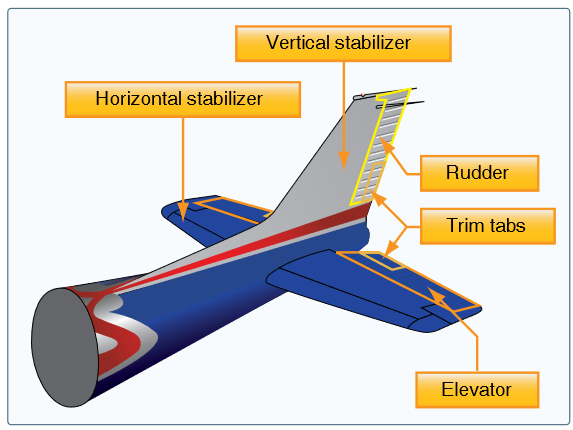

Empennage

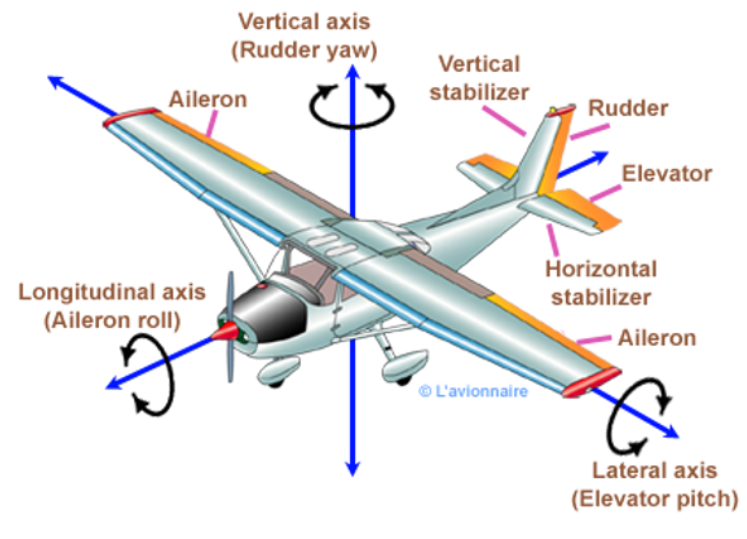

The empennage includes the entire tail group and consists of fixed surfaces, such as the vertical stabilizer and the horizontal stabilizer. The movable surfaces include the rudder, the elevator, and one or more trim tabs.

The rudder is attached to the back of the vertical stabilizer. During flight, it is used to move the airplane’s nose left and right. The elevator, which is attached to the back of the horizontal stabilizer, is used to move the nose of the airplane up and down during flight. Trim tabs are small, movable portions of the trailing edge of the control surface. These movable trim tabs, which are controlled from the flight deck, reduce control pressures. Trim tabs may be installed on the ailerons, the rudder, and/or the elevator.

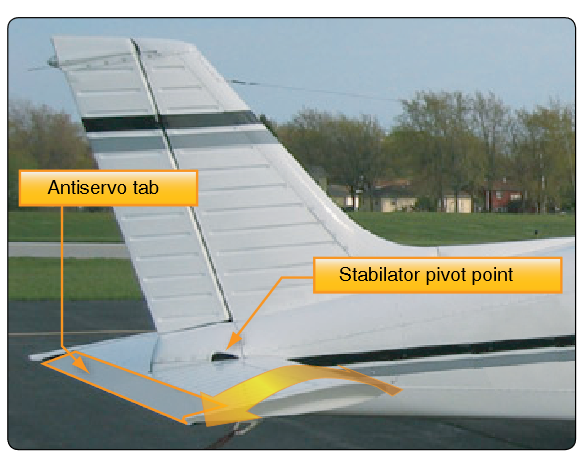

A second type of empennage design does not require an elevator. Instead, it incorporates a one piece horizontal stabilizer that pivots from a central hinge point. This type of design is called a stabilator and is moved using the control wheel, just as the elevator is moved. For example, when a pilot pulls back on the control wheel, the stabilator pivots so the trailing edge moves up. This increases the aerodynamic tail load and causes the nose of the airplane to move up. Stabilators have an antiservo tab extending across their trailing edge. The antiservo tab moves in the same direction as the trailing edge of the stabilator and helps make the stabilator less sensitive. The antiservo tab also functions as a trim tab to relieve control pressures and helps maintain the stabilator in the desired position.

Landing Gear

The landing gear is the principal support of the airplane when parked, taxiing, taking off, or landing. The most common type of landing gear consists of wheels, but airplanes can also be equipped with floats for water operations or skis for landing on snow.

Wheeled landing gear consists of three wheels—two main wheels and a third wheel positioned either at the front or rear of the airplane. Landing gear with a rear mounted wheel is called conventional landing gear.

Airplanes with conventional landing gear are sometimes referred to as tailwheel airplanes. When the third wheel is located on the nose, it is called a nosewheel, and the design is referred to as a tricycle gear. A steerable nosewheel or tailwheel permits the airplane to be controlled throughout all operations while on the ground. Most aircraft are steered by moving the rudder pedals, whether nosewheel or tailwheel. Additionally, some aircraft are steered by differential braking.

The Powerplant

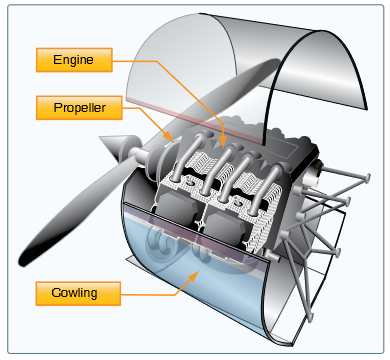

The powerplant usually includes both the engine and the propeller. The primary function of the engine is to provide the power to turn the propeller. It also generates electrical power, provides a vacuum source for some flight instruments, and in most single-engine airplanes, provides a source of heat for the pilot and passengers.

The engine is covered by a cowling, or a nacelle, which are both types of covered housing. The purpose of the cowling or nacelle is to streamline the flow of air around the engine and to help cool the engine by ducting air around the cylinders.

The propeller, mounted on the front of the engine, translates the rotating force of the engine into thrust, a forward acting force that helps move the airplane through the air.

Subcomponents

The subcomponents of an airplane include the airframe, electrical system, flight controls, and brakes.

The airframe is the basic structure of an aircraft and is designed to withstand all aerodynamic forces, as well as the stresses imposed by the weight of the fuel, crew, and payload.

The primary function of an aircraft electrical system is to generate, regulate, and distribute electrical power throughout the aircraft.

The flight controls are the devices and systems that govern the attitude of an aircraft and, as a result, the flight path followed by the aircraft. In the case of many conventional airplanes, the primary flight controls utilize hinged, trailing- edge surfaces called elevators for pitch, ailerons for roll, and the rudder for yaw. These surfaces are operated by the pilot in the flight deck or by an automatic pilot.

In the case of most modern airplanes, airplane brakes consist of multiple pads (called caliper pads) that are hydraulically squeezed toward each other with a rotating disk (called a rotor) between them. The pads place pressure on the rotor which is turning with the wheels. As a result of the increased friction on the rotor, the wheels inherently slow down and stop turning. The disks and brake pads are made either from steel, like those in a car, or from a carbon material that weighs less and can absorb more energy. Because airplane brakes are used principally during landings and must absorb enormous amounts of energy, their life is measured in landings rather than miles.

Composite Materials in Aircraft

Composite materials are fiber-reinforced matrix systems. The matrix is the “glue” used to hold the fibers together and, when cured, gives the part its shape, but the fibers carry most of the load. There are many different types of fibers and matrix systems.

The most common reinforcing fibers used in aircraft construction are fiberglass and carbon fiber. Fiberglass has good tensile and compressive strength, good impact resistance, is easy to work with, and is relatively inexpensive and readily available. Its main disadvantage is that it is

somewhat heavy, and it is difficult to make a fiberglass load- carrying structure lighter than a well designed equivalent aluminum structure.

Carbon fiber is generally stronger in tensile and compressive strength than fiberglass and has much higher bending stiffness. It is also considerably lighter than fiberglass. However, it is relatively poor in impact resistance; the fibers are brittle and tend to shatter under sharp impact.

Advantages of Composites

Composite construction offers several advantages over metal, wood, or fabric, with its lighter weight being the most frequently cited. Lighter weight is not always automatic. It must be remembered that building an aircraft structure out of composites does not guarantee it will be lighter; it depends on the structure, as well as the type of composite being used.

A more important advantage is that a very smooth, compound curved, aerodynamic structure made from composites reduces drag.

Lack of corrosion is a third advantage of composites. Boeing is designing the 787, with its all-composite fuselage, to have both a higher pressure differential and higher humidity in the cabin than previous airliners. Engineers are no longer as concerned about corrosion from moisture condensation on the hidden areas of the fuselage skins, such as behind insulation blankets. This should lead to lower long-term maintenance costs for the airlines.

Another advantage of composites is their good performance in a flexing environment, such as in helicopter rotor blades. Composites do not suffer from metal fatigue and crack growth as do metals. While it takes careful engineering, composite rotor blades can have considerably higher design lives than metal blades, and most new large helicopter designs have all composite blades, and in many cases, composite rotor hubs.

Disadvantages of Composites

Composite construction comes with its own set of disadvantages, the most important of which is the lack of visual proof of damage. Composites respond differently from other structural materials to impact, and there is often no obvious sign of damage.